CNC Machining company in USA is vital Precision Manufacturing

Introduction

In today’s competitive manufacturing landscape, CNC machining company in USA play a crucial role in delivering precision-engineered components for various industries. CNC machining, or Computer Numerical Control machining, is essential in producing intricate parts with high accuracy and consistency, from automotive and aerospace to medical and electronics sectors. This article explores why CNC machining is so vital to precision manufacturing and how it supports technological advancement in the USA.

How CNC Machining Works

Understanding the CNC Process

CNC machining company in USA involves using pre-programmed computer software to control machinery and tools in creating precise, complex parts. The process begins with a digital model that outlines the exact specifications for a component. The software then translates these specifications into a series of commands, directing the machine to follow precise movements and create the part. This controlled automation ensures that every component produced meets exact standards, reducing the potential for human error.

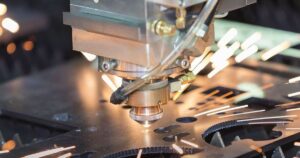

Key Equipment and Techniques

CNC machining companies in the USA utilize various machines such as CNC mills, lathes, and routers, each specialized for different types of materials and designs. The equipment allows manufacturers to work with materials like metals, plastics, and composites. Additionally, techniques such as drilling, milling, and turning are employed to achieve the desired shape and finish. This versatility in materials and techniques is why CNC machining is a preferred method across multiple industries for high-precision parts.

Advantages of CNC Machining in the USA

High Precision and Accuracy

The precision provided by CNC machining is unmatched, making it indispensable in industries where accuracy is critical. The process can achieve tolerances as tight as a few microns, ensuring that each part meets exact specifications. For companies producing complex components, such as those in the aerospace and medical industries, CNC machining provides the necessary accuracy to create parts that are both functional and safe.

Consistency and Repeatability

One of the biggest advantages of CNC machining is its ability to produce identical parts in large volumes without sacrificing quality. Once a program is set up, the machine can replicate the process repeatedly, delivering consistent results across thousands of units. This consistency is essential for sectors like automotive and electronics, where each part must meet uniform standards to ensure compatibility and performance.

Applications of CNC Machining in Various Industries

Automotive and Aerospace Manufacturing

In automotive and aerospace manufacturing, CNC machining is essential for producing components that require high strength and precision. Parts like engine components, fuel injectors, and turbine blades must be manufactured with extreme accuracy to withstand high-stress environments. CNC machining company in USA are instrumental in supporting these industries by delivering parts that meet rigorous safety and performance standards.

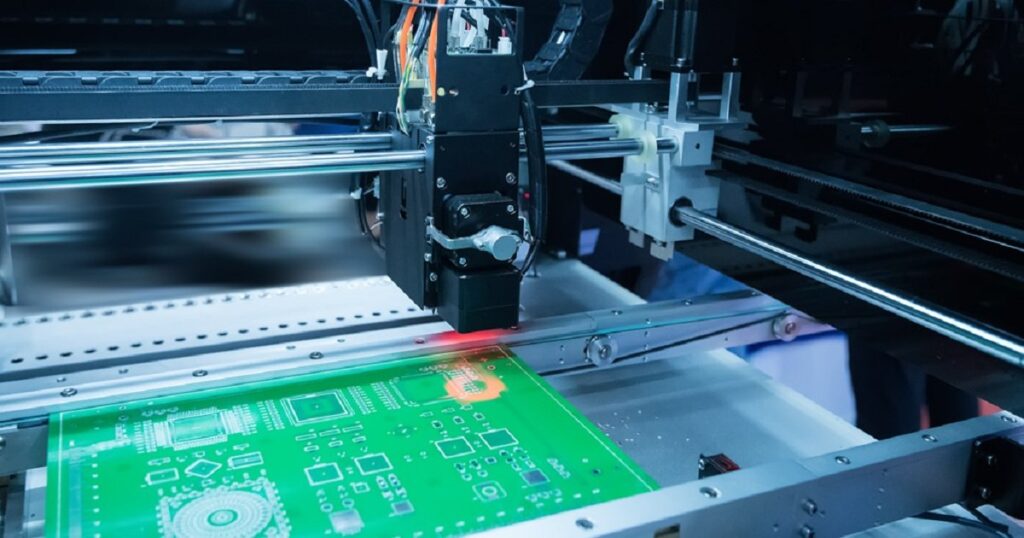

Medical and Electronics Sectors

The medical and electronics sectors also benefit greatly from CNC machining. Medical equipment, such as prosthetics and surgical instruments, require meticulous accuracy to ensure patient safety. In electronics, CNC machining produces circuit boards, connectors, and other components that demand high precision. The role of CNC machining in these sectors demonstrates its versatility and importance in applications that require high standards of reliability and precision.

Benefits of Choosing USA-Based CNC Machining Companies

Quality Assurance and Compliance

CNC machining companies in the USA adhere to stringent quality standards, often obtaining certifications such as ISO 9001 to guarantee product quality. These companies prioritize rigorous testing and quality assurance at every production stage, ensuring that each component meets the necessary standards. For businesses that rely on high-quality parts, choosing a USA-based CNC machining company ensures compliance with industry-specific regulations and enhances overall reliability.

Efficient Communication and Customer Support

Working with CNC machining company in USA facilitates clear communication, allowing businesses to discuss their specific needs in detail. The time zone alignment and language compatibility simplify collaboration, reducing the likelihood of misunderstandings. Furthermore, domestic companies often offer dedicated customer support, providing clients with real-time updates and addressing concerns promptly.

CNC Machining and Technological Advancements

Adoption of Automation and Robotics

CNC machining companies in the USA are increasingly incorporating automation and robotics to improve efficiency and reduce production costs. Robots are used for tasks such as loading and unloading materials, allowing human workers to focus on quality control and complex programming tasks. Automation enhances productivity, ensuring parts are produced quickly while maintaining precision, making it possible to meet tight deadlines in competitive industries.

Integration of AI and IoT in CNC Processes

Many USA-based CNC machining companies are integrating Artificial Intelligence (AI) and the Internet of Things (IoT) into their operations. AI algorithms analyze data to optimize machining processes, while IoT sensors monitor machinery in real time, alerting operators to potential issues before they impact production. This technology-driven approach enhances quality control and reduces downtime, resulting in more efficient and cost-effective manufacturing.

Supporting Innovation Through Customization

Ability to Produce Custom Components

CNC machining companies in the USA offer significant customization options, allowing businesses to create parts tailored to their specific needs. Customization is especially valuable for industries that require unique parts with precise measurements, such as medical device manufacturers and aerospace companies. This capability allows businesses to innovate freely, designing new products like automatic sensor doors, and improving existing ones without limitations.

Rapid Prototyping for Product Development

USA-based CNC machining companies support rapid prototyping, which is crucial for product development. Prototyping allows companies to test new designs and make adjustments before full-scale production. With CNC machining, prototypes can be created quickly and accurately, enabling businesses to refine their products based on real-world performance data. This process supports innovation by reducing the time it takes to bring new products to market.

Conclusion

CNC machining company in USA are integral to precision manufacturing, offering unmatched accuracy, consistency, and customization across various industries. By adopting advanced technology and automation, these companies enhance their capabilities, meeting the demands of sectors that require high-performance parts. For businesses seeking quality, efficiency, and innovation, USA-based CNC machining companies provide a reliable solution to achieve their manufacturing goals.

FAQs

What industries benefit the most from CNC machining in the USA?

Industries such as aerospace, automotive, medical, and electronics benefit significantly from CNC machining due to its high precision and consistency.

How does CNC machining ensure high precision?

CNC machining uses pre-programmed software to control the equipment, allowing for intricate designs and tight tolerances that meet precise specifications.

Are USA-based CNC machining companies environmentally conscious?

Yes, many USA-based CNC machining companies prioritize sustainable practices, including energy-efficient machinery and eco-friendly material sourcing.

What role does automation play in CNC machining?

Automation in CNC machining improves efficiency by streamlining production processes, reducing human error, and enabling faster production times.

Why is customization important in CNC machining company in USA?

Customization allows businesses to create unique parts for specific applications, facilitating innovation and enabling the development of advanced products.

More Stories

The Importance of Taxi Dispatch Services in the USA

Taxi Dispatch Services: The Backbone of Modern Transportation in the USA