Introduction

The manufacturing industry, a cornerstone of economic progress, is rapidly evolving in the face of technological advancements. With increased demand for efficiency, precision, and customization, manufacturing companies are looking to leverage modern IT services to stay competitive. Manufacturing IT services play a critical role in driving efficiency, quality, and cost-effectiveness, enabling manufacturers to stay agile in a fast-paced market. Additionally, digital transformation in manufacturing is reshaping the industry, pushing companies to embrace innovative solutions to streamline operations, enhance decision-making, and improve customer experiences. This article explores the essential role IT services play in modern manufacturing and highlights how they can drive digital transformation.

The Role of IT Services in Manufacturing

IT services provide manufacturers with a range of tools and solutions to streamline processes, improve accuracy, and reduce waste. Through advanced technologies like the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), and data analytics, IT services help companies transform traditional manufacturing methods into intelligent, automated operations. Here’s how IT services are critical in several key areas:

- Process Automation and Efficiency

- One of the primary benefits of manufacturing IT services is the automation of repetitive and time-consuming tasks. Automated processes reduce human error, increase speed, and allow workers to focus on high-value tasks, ultimately improving productivity. With tools like robotic process automation (RPA) and AI-driven systems, manufacturers can automate everything from production lines to inventory management, significantly boosting efficiency.

- For example, an AI-powered system can automate quality checks on the production line, identifying defective products in real time. This not only saves time and labor but also ensures that only high-quality products make it to market.

- Data-Driven Decision Making

- Manufacturing processes generate a wealth of data. IT services enable companies to capture, analyze, and leverage this data to make informed decisions. With data analytics and business intelligence tools, manufacturers gain insights into operational performance, customer preferences, and market trends.

- Predictive analytics, for instance, can help manufacturers foresee equipment failures before they happen, minimizing costly downtime and maintenance expenses. Furthermore, real-time analytics can optimize supply chain decisions, reducing lead times and enhancing production planning.

- Supply Chain Optimization

- The modern manufacturing landscape demands a responsive and efficient supply chain. Manufacturing IT services allow for seamless integration and communication between different parts of the supply chain, from suppliers and warehouses to transportation and distribution. Technologies such as blockchain can provide secure, transparent tracking of goods, ensuring traceability and accountability across the supply chain.

- Additionally, IoT-enabled sensors and cloud-based platforms can track inventory levels in real time, alerting manufacturers when supplies are low. This helps avoid production delays and reduces inventory holding costs, leading to a more streamlined and cost-effective supply chain.

- Enhanced Quality Control

- Quality control is crucial for maintaining brand reputation and customer satisfaction. Advanced IT solutions like computer vision and AI are being used to improve quality assurance. These technologies enable manufacturers to detect anomalies in products with incredible accuracy, preventing defective items from leaving the facility.

- By integrating IT services into quality control processes, manufacturers can maintain consistent standards, reduce waste, and enhance overall product quality. Digital solutions also facilitate better record-keeping, ensuring compliance with regulatory standards and easing the audit process.

- Real-Time Monitoring and Predictive Maintenance

- The integration of IT services with IoT devices allows for continuous monitoring of machinery and equipment. IoT sensors collect data on parameters like temperature, pressure, and vibration, which can signal potential issues before they escalate into costly repairs. With predictive maintenance, manufacturers can plan maintenance activities based on actual equipment conditions, rather than following a fixed schedule.

- Predictive maintenance not only helps reduce downtime but also extends the lifespan of equipment and minimizes unexpected production halts. This level of monitoring and predictive analysis is only possible with a robust IT infrastructure that supports data collection, processing, and storage.

- Cybersecurity and Data Protection

- As manufacturing processes become increasingly digitized, companies are exposed to a greater risk of cyber threats. Protecting sensitive data and ensuring secure operations have become top priorities. IT services provide the necessary cybersecurity measures to protect manufacturing operations from data breaches, ransomware attacks, and other cyber threats.

- IT providers offer solutions like firewalls, encryption, secure access protocols, and employee training to enhance cybersecurity. Moreover, with regular updates and continuous monitoring, manufacturers can stay vigilant against emerging threats, safeguarding their assets and customer data.

How IT Services Drive Digital Transformation in Manufacturing

Digital transformation in manufacturing is not just about implementing new technologies; it’s a comprehensive approach that integrates digital solutions into every aspect of production and operations. IT services play a critical role in this transformation, enabling manufacturers to evolve from traditional, siloed systems to integrated, smart manufacturing environments.

- Smart Factory and Industry 4.0

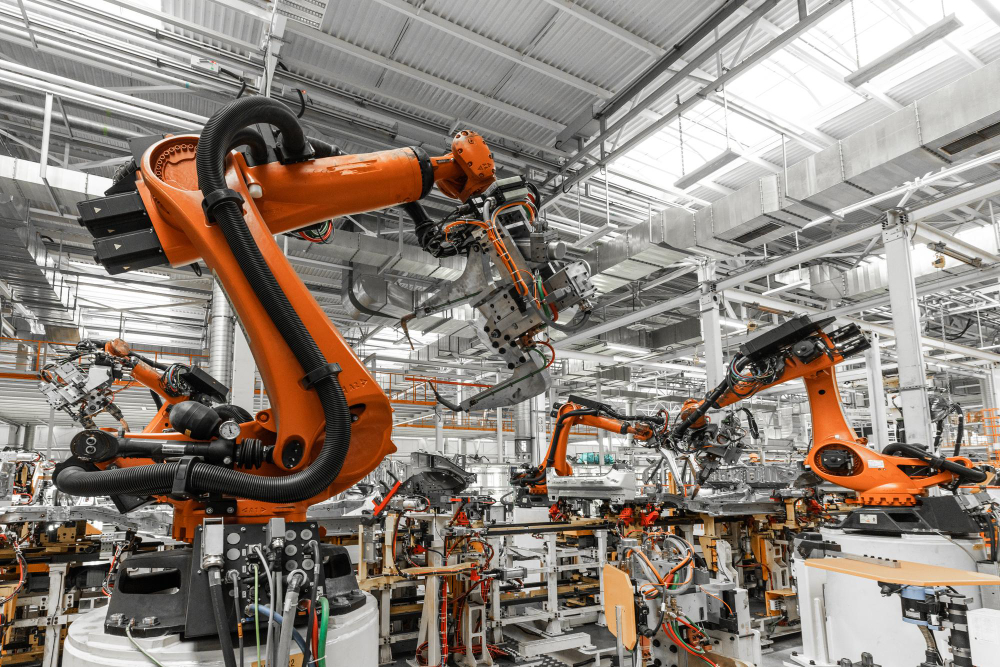

- Industry 4.0 represents the next phase of manufacturing, where smart factories leverage connected systems, automation, and data-driven insights. IT services are essential for setting up these smart factories, facilitating connectivity between devices and systems, and creating a seamless flow of information.

- In a smart factory, IT services help integrate diverse technologies like IoT, robotics, and cloud computing. This connected environment allows manufacturers to achieve unprecedented levels of flexibility, efficiency, and accuracy in their production processes.

- Digital Twins and Simulation

- Digital twin technology creates a virtual replica of physical assets, enabling manufacturers to simulate, test, and optimize processes before implementing them in the real world. IT services make it possible to build and maintain digital twins, providing manufacturers with valuable insights and predictive capabilities.

- Through simulations, manufacturers can experiment with different scenarios, identify potential bottlenecks, and optimize workflows without disrupting actual operations. This helps reduce costs, improve product quality, and accelerate time-to-market.

- Collaboration and Remote Operations

- Digital transformation has enabled greater collaboration across teams, regardless of their physical location. Cloud-based solutions allow manufacturers to work with remote teams, share critical data, and collaborate on projects in real time. IT services are essential in setting up and maintaining these collaborative tools, which have become even more crucial in the post-pandemic era.

- Additionally, remote monitoring solutions allow managers and operators to oversee manufacturing processes from anywhere, improving flexibility and responsiveness. This capability has proven valuable for manufacturers with global operations, enabling them to manage production lines and supply chains more effectively.

- Enhanced Customer Experiences

- Today’s customers expect a high level of customization and timely delivery. Digital transformation enables manufacturers to offer more personalized products, faster order processing, and transparent communication. IT services provide the technology backbone that allows manufacturers to collect customer data, understand their needs, and deliver tailored solutions.

- By integrating customer relationship management (CRM) systems with production and logistics, manufacturers can improve customer experiences, strengthen brand loyalty, and gain a competitive edge in the market.

Overcoming Challenges with IT Services in Manufacturing

While the benefits of IT services in manufacturing are substantial, companies may face certain challenges during implementation. Some of these include high initial costs, potential disruptions, and the need for skilled personnel to manage and maintain new technologies. However, these challenges can be mitigated with strategic planning and by partnering with experienced IT service providers.

- Addressing Skill Gaps

- The integration of advanced IT services requires a skilled workforce familiar with modern tools and technologies. Manufacturers can address skill gaps by investing in employee training programs or collaborating with IT providers that offer comprehensive support and training.

- Scalability and Cost-Effectiveness

- For small and medium-sized manufacturers, scaling IT solutions can be a challenge. IT service providers offer scalable solutions, such as cloud computing, that allow companies to expand their capabilities without significant upfront investments.

- Ensuring Continuous Improvement

- As technology evolves, manufacturers need to continuously update their IT infrastructure to stay competitive. Regular upgrades, maintenance, and performance reviews are essential to ensure that manufacturing IT services continue to meet operational demands and support growth.

Conclusion

The manufacturing industry is in the midst of a profound transformation driven by advanced IT services. From enhancing productivity and quality control to enabling digital transformation in manufacturing, IT services are essential for modern manufacturing operations. By investing in robust IT solutions, manufacturers can unlock new levels of efficiency, adapt to market changes, and deliver superior products and experiences to customers.

In an era where technological innovation is key to staying ahead, manufacturing IT services offer the tools and capabilities necessary to succeed. Embracing these technologies not only ensures operational excellence but also positions companies to thrive in the future of manufacturing.

More Stories

How They Are Mobile Apps Developed?

Careem Clone: How Entrepreneurs Can Build a Profitable Ride-Hailing Business

Mastering SUMOsearch: Tips and Tricks for Better Search Results